Air in a heating or cooling system causes problems

Air in your heating or cooling system disrupts the flow of water, reduces performance and forces pumps to work harder, wasting energy and increasing operating costs. Over time, it can cause noise, malfunctions, corrosion, and the accumulation of dirt or magnetite, leading to wear and tear, blockages, and expensive repairs.

By removing air, the system operates quietly, efficiently and reliably, extending its lifespan and protecting both your comfort and your budget.

A system without air breathes peace, works more economically and lasts longer

The three forms of air in system water

Did you know that system water always contains air? This air comes in three different forms, each with its own challenges to the functioning of your system:

Free Air

Microbubbles

Dissolved gasses

How do you recognise air in your heating system?

Air in your central heating system is often easy to recognise. A common signal is a bubbling or ticking sound in the pipes or radiators. You also notice it when radiators at the top stay cold while the bottom does get warm. In some cases, the boiler starts more often than necessary, or you have to bleed radiators over and over again to make the system work properly.

All these signals indicate that there is air in the system, which hinders the flow and reduces the efficiency. The sooner you recognise this, the better you can prevent bigger problems.

Removing all these forms of air is essential to keep your system running efficiently, quietly, and sustainably.

Check out what air in your heating system means!

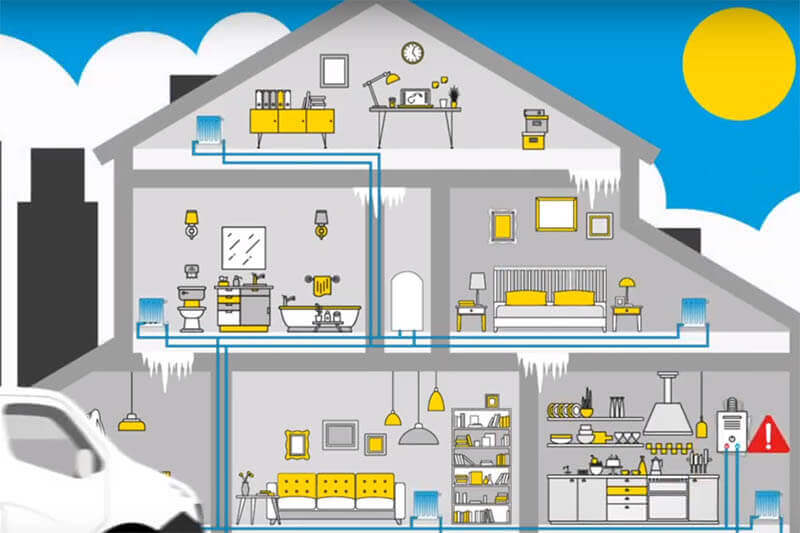

Where do you place an air vent or vacuum degasser in your installation?

The correct placement of an air vent or vacuum degasser is crucial to effectively remove air from your installation. Here are the most important guidelines:

Air vent (SpiroTop)

A SpiroTop air vent should be placed at the highest point of your heating or cooling installation. This prevents air from accumulating in so-called air pockets, so that the flow remains optimal.

Microbubble air vent (SpiroVent)

Microbubble air vents work best at the warmest point in your system:

- When heating: Place the SpiroVent where the system water exits the boiler.

- When cooling: Place the SpiroVent where the water enters the system.

Vacuum degasser (SpiroVent Superior)

The position of a vacuum degasser is less critical, as it works with a vacuum to remove dissolved gases from the water.

Choose the right solution and place it where it is most effective, for a hassle-free and efficient system.

The perfect solution for any installation

Can't predict exactly where air will be released in your system? Then it is difficult to determine where to place an air separator. In such cases, a vacuum degasser is the ideal choice. This solution works throughout the system and prevents air problems, even in places where gas build-up is difficult to predict.

When is a vacuum degasser the best choice?

Here are some situations where gas buildup is tricky to predict:

- Large differences in altitude in your system, above the hottest point

- Underfloor heating with pipes that are not completely flat

- Low-temperature heating with a low flow temperature

- Heat pumps with low heat transfer temperatures in the heat exchanger

With a vacuum degasser, you are always assured of an air-free system, regardless of the complexity of the installation. It is the smart solution to a problem that you would otherwise not be able to fully control.

What is vacuum degassing?

A vacuum degasser subjects system water to very low pressure, far below atmospheric pressure, and this releases the dissolved gasses.

Water, by its very nature, absorbs gases easily until saturated. The level of saturation depends on the pressure and temperature. At low pressures, less gas can be absorbed. Vacuum degassing treats water from the system in small set volumes. The water is subjected to vacuum pressure, releasing all the dissolved gases. It is a bit like opening a fizzy drinks bottle. As soon as you start to unscrew the cap, you hear and see the gas appear.

The small volumes of degassed water are returned to the system. The system water is now “hungry” for gas and quickly dissolves any gas pockets it encounters in the system. The saturated water is fed back to the degasser and once again subjected to a vacuum to remove the dissolved gases.

Vacuum degassing uses Henry's law, the affect of pressure and temperature on the absorbent capacity of water in degassing situations, to keep the entire system free of air/gas.

Our solutions for effective air removal